Introduction

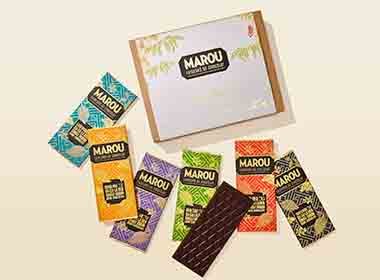

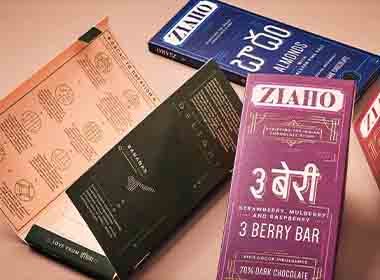

From convenience store counters to boutique chocolatiers, chocolate bars remain one of the most iconic and accessible forms of confectionery. But behind every bar is more than just great flavor—it’s also about how it’s wrapped, boxed, and presented. As consumer expectations evolve, so too must packaging.

This guide is designed to help chocolate brands navigate the many choices in chocolate bar box packaging, offering insights into material selection, structural formats, and finishing options that influence both branding and sustainability.

1. A Brief History of the Chocolate Bar

While cacao has been consumed for over 3,000 years—dating back to the Mayans and Aztecs, who drank it as a bitter ceremonial beverage—the chocolate bar as we know it didn’t emerge until the mid-1800s.

- In 1847, Fry’s of Bristol created the first moldable chocolate bar using a blend of cocoa powder, sugar, and cocoa butter.

- Soon after, Cadbury and Nestlé followed, developing their own versions of solid chocolate bars for everyday consumption.

- Hershey’s, founded in 1894, was among the first to mass-produce chocolate bars in North America, making them affordable and accessible.

Early Packaging

- Initially, chocolate bars were wrapped in wax paper and tin foil to preserve freshness.

- In the 20th century, brands began using printed outer paper sleeves for branding.

- Today, high-end chocolate bars are often sold in custom paperboard boxes for a premium, giftable feel.

2. What Is a Chocolate Bar Box?

A chocolate bar box is typically made from folding carton (paperboard) or rigid board and is designed to protect the product, support brand messaging, and ensure food safety.

Unlike flexible wrappers (used for mass-market chocolate bars), boxes are often chosen for:

- Premium or artisan chocolate lines

- Sustainable, plastic-free packaging goals

- Seasonal or gift-oriented packaging needs

- Retail settings where shelf appeal is critical

Chocolate bar boxes serve three essential functions:

- Protection – safeguarding chocolate from light, moisture, and mechanical damage.

- Presentation – enhancing visual branding and storytelling.

- Practicality – allowing for easy stacking, handling, and retail display.

3. Packaging Materials and Finishes

Choosing the right packaging material is key to balancing cost, sustainability, and print quality. Most chocolate bar boxes use paper-based materials that can be printed and formed into various shapes with or without plastic lamination.

Here are some common material choices:

- C1S (Coated One Side) Paperboard

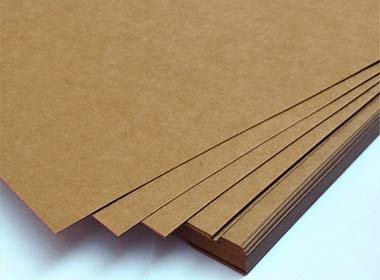

Smooth surface on one side for high-quality printing. Ideal for most branded chocolate bar cartons. - Kraft Paperboard

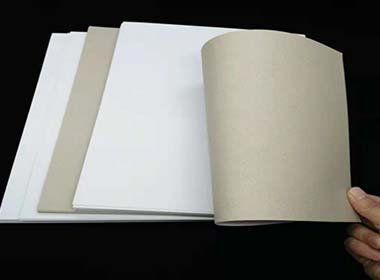

Natural brown color and textured look. Great for organic or “earth-friendly” positioning. - Greyboard (Rigid)

Thicker and more durable, used in premium gifting or multi-bar sets. - Coated Duplex Board

Coated on both sides, often used for heavier or dual-sided printing needs.

Surface finishing can include:

- Matte or gloss lamination

- Hot foil stamping

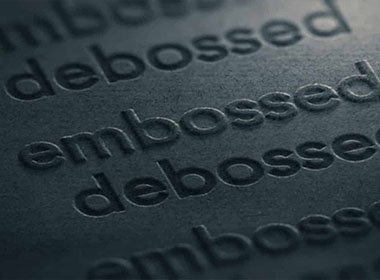

- Embossing/debossing

- Spot UV or soft-touch varnish

📊 Table 1: Common Chocolate Bar Box Materials & Finishes

| Material Type | Features | Common Use Case |

|---|---|---|

| C1S Paperboard | Smooth print surface, cost-effective | Standard brand packaging |

| Kraft Paperboard | Natural look, recyclable, eco appeal | Organic/artisan chocolate lines |

| Rigid Greyboard | High-end feel, strong protection | Premium gift bar sets |

| Coated Duplex Board | Dual-sided coating, durable for retail use | Heavier cartons or multi-bar packs |

4. Printing Techniques for Chocolate Bar Boxes

The printing process plays a central role in creating an appealing chocolate bar box that draws attention on retail shelves and aligns with brand aesthetics.

Common Printing Techniques:

- Offset Printing

The industry standard for chocolate packaging—ideal for sharp text, vivid graphics, and large volume runs. It delivers consistent results on coated and uncoated paperboard. - Hot Foil Stamping

Often used to highlight logos, borders, or festive elements. Available in gold, silver, holographic, or custom colors. - Embossing/Debossing

Creates a tactile impression—either raised or indented—that gives a luxury feel. Frequently used for logos or artisanal lines. - Spot UV and Soft-Touch Lamination

Spot UV adds gloss to selected areas, while soft-touch coatings give a velvet-like finish. These enhance tactile engagement and perceived quality. - Food-Grade Coating Options

Inner layers can be coated with anti-grease or food-safe varnishes to prevent oil migration and ensure freshness.

These techniques help communicate brand identity and perceived product quality, especially in markets where visual storytelling drives purchase decisions.

5. Structural Designs and Custom Box Styles

While the chocolate bar format is standardized in size, the box structures used to house them vary greatly depending on market positioning and use case. Whether you’re selling a single bar or a bundle, choosing the right box shape impacts cost, functionality, and presentation.

📊 Table 2: Chocolate Bar Box Styles Overview

| Box Style | Structure Type | Best For |

|---|---|---|

| Reverse Tuck End | Folding Carton | Standard chocolate bar packaging |

| Straight Tuck End | Folding Carton | Premium printed bars with window |

| Sleeve + Tray | Folding or Rigid | Seasonal sets, dual-layer packaging |

| Auto-Lock Bottom | Folding Carton | Heavier bars or bulkier products |

| Book-Style Magnet Box | Rigid Box | Gift packs, limited editions |

Choosing the Right Structure

- Tuck-end boxes are ideal for standard bars and allow quick manual or automated packing.

- Sleeve boxes offer a clean outer surface and protect a foil-wrapped bar inside—perfect for boutique or eco-focused brands.

- Rigid book-style boxes can turn a simple bar into a luxury gift, often used for festive collaborations or special collections.

If sustainability is a key goal, brands may opt for glue-free lock structures, paper-only inserts, or modular designs that allow easy separation for recycling.

Conclusion

CChocolate bar boxes are more than just packaging—they’re part of the overall product experience. With the right combination of material, design, and printing, your packaging can protect the product, reflect brand values, and appeal to evolving consumer expectations.

Whether you’re creating everyday wrappers or high-end gift boxes, a well-designed chocolate bar box can:

- Increase shelf appeal

- Improve customer perception

- Support sustainability goals

- Enhance brand storytelling

As more brands shift toward premium presentation and eco-conscious materials, chocolate bar packaging is becoming as refined as the chocolate inside.

If you’re looking for inspiration or tailored solutions for your next project, explore our range of custom chocolate bar box packaging options designed to fit every brand style and market need.