Introduction

Custom chocolate packaging plays a vital role in product presentation, protection, and branding. However, many businesses—especially first-time buyers—often have questions before starting their custom project.

This FAQ gathers the most common inquiries based on industry standards, providing practical answers to help you plan smoothly.

1. What is the minimum order quantity (MOQ) for custom chocolate packaging?

Most chocolate packaging manufacturers require a minimum order quantity (MOQ) of around 1,000 pieces per design.

Some simpler packaging types, such as folding cartons for chocolate bars, may allow a lower MOQ starting from 500 pieces, but costs per unit will be slightly higher at lower quantities.

2. Is there a charge for making a sample (proofing)?

Generally, manufacturers do charge a sampling fee, usually between $100 and $300, depending on the box type, size, and finishes involved.

The sampling fee often covers manual setup and material costs and is commonly refundable or deductible once a mass production order is placed.

3. How long does the production cycle take for custom chocolate packaging?

The typical production cycle for custom chocolate packaging is about 15 to 25 working days after final sample approval.

Complex designs (such as magnetic boxes or special printing effects) may take longer.

It’s recommended to start the customization process at least 2–3 months before the intended launch or promotional event.

4. What materials are available for custom chocolate boxes?

Most manufacturers offer a wide range of materials, including:

- Rigid paperboard: Premium, sturdy option for high-end gift packaging.

- Coated folding carton: Lightweight, cost-effective solution for retail chocolate bars.

- Kraft paper: Natural, recyclable choice favored for sustainable branding.

- FSC-certified paper: Environmentally responsible option for eco-conscious brands. Each material can be customized with different thicknesses, textures, and finishing effects according to brand needs.

5. What file format should I prepare for the design artwork?

Print-ready files should be provided in vector formats such as AI (Adobe Illustrator) or high-resolution PDF.

Designs must include a 3–5mm bleed margin to prevent cutting errors, and all text should be outlined to ensure accuracy during printing.

Most suppliers can provide a dieline template to help designers correctly position artwork based on the box structure.

6. How long does it take to ship the finished packaging to my country?

Shipping time depends on the destination and shipping method:

- By air: About 5–10 days to major markets like the USA, Europe, and Australia.

- By sea: About 20–40 days, depending on the port and customs clearance. Express shipping options are available for urgent small-batch orders, but costs will be higher.

7. Do manufacturers provide packaging design services?

Some packaging manufacturers offer basic design support, such as helping adjust artwork to fit dielines or suggesting improvements for print quality.

However, full branding and creative design services (like creating a logo or brand story) usually require cooperation with a specialized design agency.

It’s advisable to have your branding elements prepared in advance to speed up the process.

8. Can I customize internal inserts for the chocolate box?

Yes, most chocolate packaging manufacturers allow full customization of internal inserts to fit different chocolate shapes and sizes.

Common insert options include:

- Paperboard trays (cost-effective, recyclable)

- Foam inserts (providing better cushioning)

- Molded pulp trays (eco-friendly and sturdy) Choosing the right insert ensures the chocolates are well protected during transport and enhances the unboxing experience.

9. What finishes and printing effects can I add to my chocolate packaging?

There are many finishing options available to elevate the look and feel of your packaging, such as:

- Matte or gloss lamination

- Hot foil stamping (gold, silver, holographic)

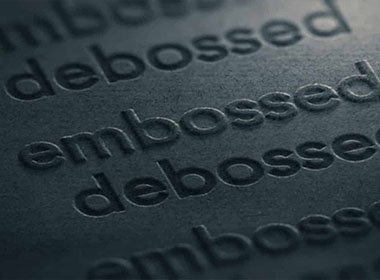

- Embossing and debossing

- Spot UV coating

- Textured papers (linen, velvet-touch) Different finishes can dramatically affect both the visual appeal and cost, so it’s important to balance aesthetics and budget.

10. What should I prepare before starting a custom packaging order?

Before contacting a supplier, it’s helpful to have the following ready:

- Estimated order quantity

- Box style and rough size

- Preferred materials and finishes

- Brand artwork or design files

- Target delivery date Clear initial information helps manufacturers provide accurate quotations and shorten the development timeline.

Conclusion

Ordering custom chocolate packaging for the first time may seem complicated, but with the right preparation and communication, the process becomes much smoother.

By understanding key factors such as minimum order quantity, production timelines, material options, and artwork requirements, you can avoid common pitfalls and create packaging that enhances your brand value.

If you have further questions, most professional packaging suppliers are happy to provide samples, consultations, and technical support to ensure your project’s success.